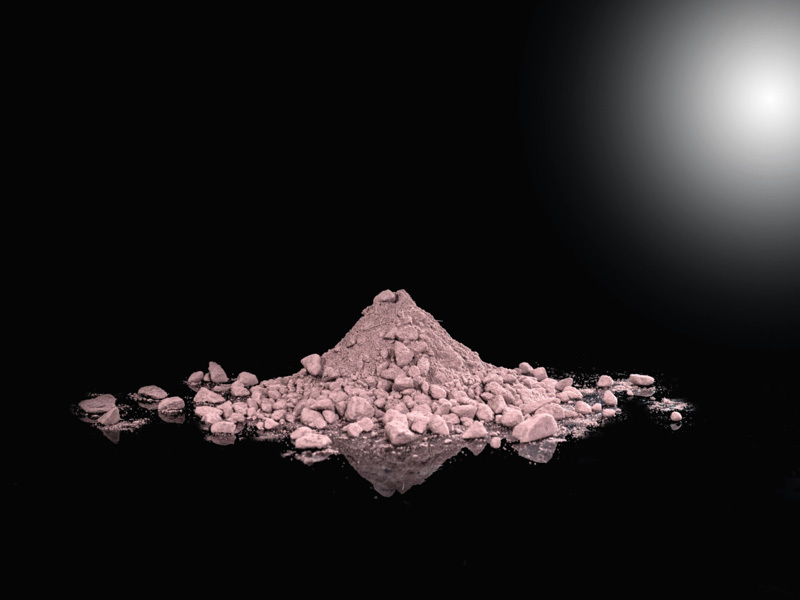

Induction coil mortar

Classification:

Product Introduction

This product is applied to the inner surface of the coreless induction furnace inductor coil coating material. has the following characteristics:

Protection of induction coil: this product has good high temperature performance, once the metal liquid into the furnace lining, play a role in protecting the coil from metal liquid corrosion.

Support induction coil: prevent it from deforming when using and removing the furnace lining, especially for the furnace body with ejection mechanism, it has the function of guiding and preventing the coil from being scratched.

Protection of intermediate frequency power supply: it has good insulation performance. After coating mastic between induction coil turns, it can prevent short circuit or discharge between coil turns from causing excessive impact current to burn out thyristor, etc.

Main physical and chemical indexes of induction coil cement

| Performance index | Parameters | |

| Chemical composition (%) | Al₂O₃ ;≥ | 70 |

| CaO | 10 | |

| Fe₂O₃ ;≤ | 2.5 | |

| Physical Performance | Bulk density (g/cm³);≥ | 2.4 |

| Particle size (mm);≤ | 3 | |

| Compressive strength 110 ℃× 24h (MPA);≥ | 35 | |

25 kg/bag, can be stored for 4 months in a cool and dry environment.

High strength polyester paper composite film packaging. Please store in a dry place to prevent moisture.

Construction method: with trowel wipe, add water: 10-13%.

Key words:

Induction coil mastic

Related Products

Product inquiry