Company Profile

Jiaozuo Jinxin Hengtuo Advanced Material Co., Ltd. was founded in 2011. It is located in Jiaozuo City, Henan Province, one of the civilized tourist cities in the country. It is adjacent to Yuntai Mountain, a national AAAAA-level scenic spot. After more than ten years of hard work and development, the company has been built into an industrial furnace and high-temperature kiln integrated solution service provider integrating design and development, industrial manufacturing, construction and installation, use and maintenance.

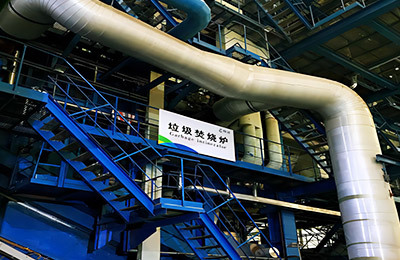

The company's business scope covers almost all refractory materials required by industrial kilns, including steel rolling reheating furnace, circulating fluidized bed boiler, gasifier, non-ferrous nickel-iron rotary kiln, lime kiln, aluminum melting furnace, mine thermal electric furnace, ladle, tundish, converter, blast furnace, one tank of iron ladle, etc. It can provide turnkey service of refractory design, manufacturing, construction and masonry of industrial furnaces and EPC projects of refractory. In the past 10 years, the company has participated in the construction of more than 3000 steel rolling reheating furnaces, accounting for more than 70% of China's newly built steel rolling reheating furnaces. In the regenerative reheating furnace heat storage boxes, burner bricks, anchor bricks, ceramic honeycomb, baking-free quick-drying explosion-proof series castable, one tank of iron ladle, etc., there are a number of key technologies in the domestic level.

The company has now built two fully automated and smart production lines with an annual output of 150000 tons of monolithic refractories, one production line with an annual output of 20000 tons of refractory prefabricated parts and one smart production line with an annual output of 50000 tons of iron ladle bricks. Xiuwu Jinheng has an annual output of 40000 tons of high-temperature refractory products production line, an annual output of 10000 square meters ceramic honeycomb production line, an annual output of 20000 tons of light thermal insulation bricks production line, and a total production capacity of refractory products of more than 300000 tons. It has become one of the important industrial furnace aluminum silicon refractory manufacturing bases in China.

For more than ten years, the company has always been committed to providing customers with the whole process, personalized and lean services. It is a national high-tech enterprise, a "gazelle" enterprise in Henan Province (a small giant enterprise of science and technology), and a national-level specialized person "Little Giant" enterprise, with three-level qualification for general contracting of metallurgical engineering construction. Company technology center is the enterprise technology center of Henan Province, Henan Province industrial furnace refractory engineering technology research center. It has established university-enterprise scientific research cooperation with universities and research institutes such as Beijing University of Science and Technology, Wuhan University of Science and Technology, Xi'an University of Architecture and Technology, Luoyang Institute of Technology and other universities and research institutes. The company focuses on the independent research and development and innovation of high-temperature furnace technology. Now it has obtained 8 invention patents in the field of industrial furnace refractory research and development and manufacturing, applied for more than 60 core patents, and obtained 4 provincial scientific research results. Published more than 50 influential professional papers in the fields of furnace lining lightweight, energy saving and environmental protection, and revised 8 national/industry standards. The company has passed the certification of ISO 9001:2008 quality management system, ISO 14001:2004 environmental management system and GB/T 28001-2011 occupational health and safety management system.

In the future, under the leadership of the concept of green development, the company will continue to uphold the principle of "creating value for users with better quality and better service!" The company's mission, abide by the corporate values of "innovation, dedication, enterprising, and win-win", continue to devote itself to the research and development and production of energy-saving, environmental protection, green, and long-life refractories, and continue to adhere to the development concept of "technological innovation and intelligent manufacturing". A refractory enterprise group with international competitiveness in the field of industrial furnace refractories creates greater value for the green and sustainable development of high-temperature industrial furnaces.